Compact slip ring capsules play a crucial role in modern technology, enabling seamless transmission of power and signals in rotating systems. Their small size and high flexibility make them indispensable in various applications, from medical devices to robotics. The compact design of these slip rings allows them to fit into tight spaces without compromising performance. This flexibility is essential for applications that demand precise and reliable connections within confined environments. Custom slip rings, specifically designed to meet unique requirements, offer tailored solutions that enhance performance and reliability, ensuring optimal functionality in even the most challenging conditions.

Features and Benefits of Compact Slip Ring Capsules

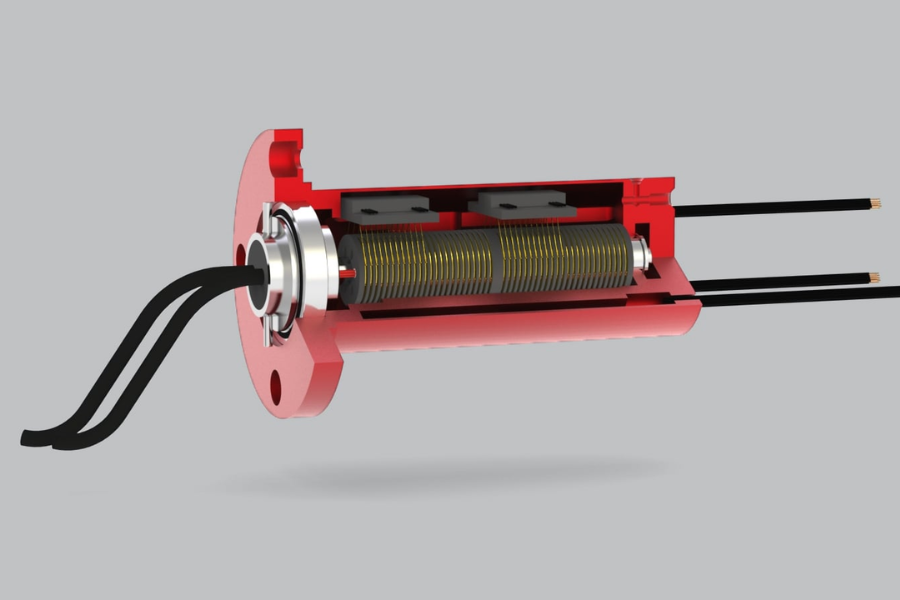

Compact slip ring capsules are pivotal components in modern rotating systems, providing critical solutions for seamless transmission of signals and power. Their innovative design and advanced technology make them suitable for a wide range of applications, from medical devices to industrial automation. This section explores the key features and benefits of compact slip ring capsules, highlighting their 360° rotating transmission capabilities and advanced gold-gold contact technology.

360° Rotating Signal/Power Transmission Capabilities

One of the most significant features of compact slip ring capsules is their ability to facilitate 360° rotating signal and power transmission. This capability ensures continuous and uninterrupted transfer of electrical signals and power between stationary and rotating parts of machinery. The benefits of this feature are manifold:

Uninterrupted Performance:

In applications where constant rotation is required, such as in robotic arms or wind turbines, the 360° rotating capability of compact slip ring capsules ensures that signals and power are transmitted without interruption. This uninterrupted performance is crucial for maintaining the operational efficiency and reliability of such systems.

Versatility:

Compact slip ring capsules can be used in a variety of applications due to their ability to handle different types of signals and power levels. Whether it’s for transmitting high-frequency data, control signals, or electrical power, these slip rings offer versatile solutions that meet the demands of diverse industries.

Space Efficiency:

The compact design of these slip rings allows them to be integrated into tight spaces where traditional slip rings may not fit. This space efficiency is particularly beneficial in applications such as medical devices, where equipment size is a critical factor.

Advanced Gold-Gold Contact Technology

Another standout feature of compact slip ring capsules is the use of advanced gold-gold contact technology. This technology provides several advantages, including low resistance, long life, and high reliability:

Low Resistance:

Gold-gold contact technology significantly reduces electrical resistance, ensuring efficient transmission of signals and power. Low resistance is essential for applications that require high precision and minimal signal loss, such as in communication systems and medical imaging devices.

Long Life:

The durability of gold contacts ensures a long operational life for the slip ring capsules. Unlike other materials that may wear out quickly, gold contacts maintain their integrity over extended periods, reducing the need for frequent replacements and maintenance.

High Reliability:

The reliability of gold-gold contacts makes compact slip ring capsules ideal for critical applications where consistent performance is paramount. For instance, in aerospace and defense systems, where failure is not an option, the use of gold contacts ensures that the slip rings can withstand harsh conditions and deliver reliable performance.

Additional Benefits of Compact Slip Ring Capsules

Enhanced Signal Integrity:

Compact slip ring capsules are meticulously designed to minimize electrical noise and interference, thereby ensuring high signal integrity. This feature is particularly crucial in applications requiring the transmission of high-fidelity data, such as advanced sensor systems and high-speed communication networks. By maintaining robust signal integrity, these capsules enable precise and reliable data transfer, essential for the optimal performance of sensitive electronic equipment.

Ease of Installation:

The compact and modular design of capsule slip ring capsules significantly simplifies installation and integration into existing systems. This user-friendly design reduces setup time and allows for quick deployment across various applications, enhancing overall efficiency. Whether in industrial automation or medical devices, the straightforward installation process ensures that systems can be up and running swiftly, minimizing downtime and operational disruptions.

Cost-Effectiveness:

Despite their advanced features, capsule slip ring capsules offer a cost-effective solution for many applications. Their durable construction and low maintenance requirements result in lower total ownership costs, making them an economically viable option for both small-scale and large-scale operations. The long lifespan of these slip rings means fewer replacements and repairs, leading to significant cost savings over time.

Flexibility in Design:

Custom capsule slip ring capsules can be tailored to meet specific application requirements, providing exceptional flexibility in design. Whether it involves adjusting the number of channels, voltage ratings, or mechanical dimensions, these slip rings can be customized to ensure optimal performance in specialized applications. This adaptability makes them suitable for a wide range of uses, from aerospace and defense to renewable energy and telecommunications.

Compact slip ring capsules represent a significant advancement in slip ring technology, offering numerous features and benefits that cater to modern technological demands. Their 360° rotating signal and power transmission capabilities, combined with advanced gold-gold contact technology, make them indispensable in a wide range of applications. The low resistance, long life, and high reliability of these slip rings ensure that they meet the rigorous demands of critical systems. Furthermore, their compact design, ease of installation, and cost-effectiveness make them a practical choice for various industries. As technology continues to evolve, the role of compact slip ring capsules in ensuring efficient and reliable transmission of signals and power will become increasingly vital.

Applications and Integration

Compact slip ring capsules are integral to numerous industries, providing essential solutions for seamless power and signal transmission in rotating systems. Their versatility and efficiency make them a preferred choice in applications where space constraints and high performance are critical. This section explores various industries and equipment that benefit from compact slip ring capsules and highlights the advantages of their compact design in space-constrained environments.

Examples of Industries and Equipment Where Compact Slip Ring Capsules Are Used

1. Medical Devices

In the medical field, precision and reliability are paramount. Compact slip ring capsules are widely used in advanced medical equipment such as MRI machines, CT scanners, and robotic surgical systems. These devices require continuous rotation and precise signal transmission for accurate diagnostics and surgical precision. The compact size of these slip rings allows them to be integrated into the tight confines of medical equipment without compromising performance.

2. Industrial Automation

Industrial automation relies heavily on robotics and automated machinery, which often operate in continuous rotational motion. Compact slip ring capsules are essential in robotic arms, automated assembly lines, and CNC machines, where they facilitate uninterrupted power and signal transmission. Their ability to fit into small spaces while providing reliable performance makes them indispensable in enhancing operational efficiency and productivity.

3. Aerospace and Defense

The aerospace and defense industries demand highly reliable and durable components due to the extreme conditions they operate in. Compact slip ring capsules are used in various aerospace applications, including satellite communication systems, radar systems, and avionics. In defense, they are crucial in surveillance equipment and missile guidance systems. Their robust design ensures reliable performance under high stress, vibration, and temperature variations.

4. Renewable Energy

Wind turbines and solar tracking systems are prime examples of renewable energy applications that benefit from compact slip ring capsules. In wind turbines, these slip rings enable the transfer of electrical signals from the rotating blades to the stationary power system. For solar trackers, they ensure the continuous transmission of power and control signals to optimize the orientation of solar panels. The compact design allows for efficient integration into these systems, promoting sustainable energy generation.

5. Telecommunications

In the telecommunications industry, ethernet slip rings play a vital role in maintaining high-speed data transmission in rotating systems such as antennas and satellite dishes. These slip rings ensure that data signals are transmitted without loss or interference, which is crucial for reliable communication. Their compact design is particularly advantageous in applications where space is limited but high performance is required.

Advantages of Compact Design in Space-Constrained Environments

1. Space Efficiency

One of the most significant advantages of compact slip ring capsules is their ability to fit into confined spaces. This is particularly beneficial in industries where equipment size and weight are critical factors. For example, in aerospace applications, every millimeter and gram counts. The compact design of these slip rings allows them to be integrated into small, complex systems without requiring significant modifications or additional space.

2. Enhanced Performance

Despite their small size, compact slip ring capsules offer high performance and reliability. The advanced technology used in these slip rings, such as gold-gold contact technology, ensures low resistance and long life. This translates to efficient power and signal transmission, which is essential for maintaining the performance of the overall system. In applications like medical devices and industrial automation, where precision and reliability are crucial, the performance benefits of compact slip ring capsules are invaluable.

3. Reduced Maintenance

The robust construction and advanced materials used in compact slip ring capsules contribute to their durability and long operational life. This reduces the need for frequent maintenance and replacements, leading to lower operational costs and minimal downtime. In industries where continuous operation is essential, such as renewable energy and telecommunications, the reduced maintenance requirements of compact slip ring capsules enhance overall system efficiency and reliability.

4. Versatile Integration

The compact design of these slip rings allows for versatile integration into various systems. They can be customized to meet specific application requirements, including different voltage ratings, channel counts, and mechanical dimensions. This versatility ensures that compact slip ring capsules can be tailored to fit the unique needs of diverse industries and applications, providing a seamless solution for power and signal transmission.

5. Cost-Effectiveness

While the initial investment in compact slip ring capsules may be higher than traditional slip rings, their long-term benefits make them a cost-effective solution. The extended operational life, reduced maintenance, and enhanced performance result in significant cost savings over time. For industries that prioritize efficiency and reliability, the cost-effectiveness of compact slip ring capsules makes them an attractive choice.

Compact slip ring capsules are crucial components in modern rotating systems, offering unparalleled benefits in terms of space efficiency, performance, and reliability. Their applications span across various industries, including medical devices, industrial automation, aerospace and defense, renewable energy, and telecommunications. The ability to integrate seamlessly into space-constrained environments while maintaining high performance and reducing maintenance requirements highlights the advantages of these advanced slip rings. As technology continues to evolve, compact slip ring capsules will play an increasingly vital role in ensuring efficient and reliable power and signal transmission in a wide range of applications.

Installation and Maintenance

Compact slip ring capsules are designed not only for high performance and reliability but also for ease of installation and minimal maintenance requirements. This section explores the various installation options available for compact slip ring capsules, emphasizing their flexibility and adaptability. Additionally, it highlights the low maintenance requirements and operational efficiency that make these components ideal for various applications.

Ease of Installation with Various Options

Flange Installation

One of the primary installation methods for compact slip ring capsules is the flange installation. Flange-mounted slip rings are designed with a flange on the outer casing that allows for secure and straightforward attachment to the mounting surface. This method offers several benefits:

Secure Mounting: The flange provides a stable base, ensuring that the slip ring remains firmly in place during operation. This is particularly important in applications involving high-speed rotation or significant mechanical stress.

Ease of Alignment: Flange mounting simplifies the alignment process, ensuring that the slip ring is correctly positioned relative to other components in the system. Proper alignment is crucial for maintaining the integrity of electrical connections and ensuring optimal performance.

Versatility: Flange-mounted slip rings can be used in a wide range of applications, from industrial machinery to medical devices, providing a reliable solution for various installation requirements.

Flangeless Installation

Another popular installation option for compact slip ring capsules is the flangeless design. Flangeless slip rings are compact and lightweight, making them ideal for applications with stringent space constraints. Key advantages of flangeless installation include:

Space Efficiency: The absence of a flange reduces the overall footprint of the slip ring, allowing it to fit into tight spaces where traditional flange-mounted designs may not be feasible.

Flexibility: Flangeless slip rings can be integrated into various systems using alternative mounting methods, such as clamps or custom brackets. This flexibility makes them suitable for unique and specialized applications.

Ease of Integration: Flangeless designs are often easier to integrate into existing systems, as they can be mounted in multiple orientations and configurations, providing a versatile solution for diverse installation challenges.

Custom Mounting Solutions

For applications with specific or unconventional requirements, custom mounting solutions can be developed. These bespoke installations are tailored to meet the unique needs of the system, ensuring optimal performance and compatibility. Custom solutions might include:

Specialized Brackets: Custom brackets can be designed to accommodate the unique dimensions and mounting requirements of the slip ring, providing a secure and stable installation.

Integrated Mounting: In some cases, slip rings can be integrated directly into the design of the machinery or device, eliminating the need for additional mounting hardware and simplifying the installation process.

Low Maintenance Requirements and Operational Efficiency

Durability and Reliability

Compact slip ring capsules are engineered for durability and reliability, utilizing high-quality materials and advanced manufacturing techniques. Key features that contribute to their low maintenance requirements include:

Gold-Gold Contacts: Many compact slip ring capsules incorporate gold-gold contact technology, which provides low resistance and high durability. These contacts are resistant to wear and corrosion, ensuring long-lasting performance with minimal maintenance.

Sealed Enclosures: Slip rings designed for harsh environments often feature sealed enclosures that protect internal components from dust, moisture, and contaminants. This protection extends the lifespan of the slip ring and reduces the need for frequent maintenance.

Self-Lubricating Materials

Some compact slip ring capsules use self-lubricating materials in their construction. These materials reduce friction and wear, eliminating the need for regular lubrication and further minimizing maintenance requirements. Self-lubricating slip rings are particularly beneficial in applications where access for maintenance is limited or where continuous operation is essential.

Operational Efficiency

The low maintenance requirements of compact slip ring capsules contribute to their overall operational efficiency. By reducing downtime and the frequency of maintenance interventions, these slip rings help maintain continuous and reliable operation, which is critical in many industrial and commercial applications. Key benefits of operational efficiency include:

Increased Uptime: With fewer maintenance interruptions, systems equipped with compact slip ring capsules can operate for longer periods, enhancing productivity and reducing operational costs.

Lower Maintenance Costs: The durability and reliability of compact slip ring capsules translate to lower maintenance costs over the lifespan of the system. This cost savings is particularly significant in applications where maintenance is challenging or costly.

Consistent Performance: The robust design of compact slip ring capsules ensures consistent performance, even in demanding conditions. This reliability is crucial for maintaining the efficiency and effectiveness of critical systems.

Compact slip ring capsules offer significant advantages in terms of ease of installation and low maintenance requirements. With various installation options, including flange and flangeless designs, they provide flexible solutions for diverse applications. The durability and reliability of these slip rings, coupled with their low maintenance needs, enhance operational efficiency and reduce costs. As a result, compact slip ring capsules are an ideal choice for industries seeking reliable and efficient solutions for their rotating systems. Whether used in industrial automation, medical devices, aerospace, or other applications, these slip rings deliver exceptional performance and value.

Future Trends and Developments

The evolution of slip ring capsule technology is driven by the constant demand for improved performance, reliability, and efficiency across various industries. This section explores the emerging technologies and trends in slip ring capsule design, as well as potential future applications and advancements that are set to shape the next generation of these critical components.

Emerging Technologies and Trends in Slip Ring Capsule Design

1. Enhanced Material Science

One of the most significant trends in slip ring capsule design is the development and utilization of advanced materials. Researchers and engineers are focusing on materials that offer superior electrical conductivity, wear resistance, and thermal stability. For example, the use of graphene and carbon nanotubes is being explored to enhance the performance and longevity of slip ring contacts.

Graphene-Based Contacts: Graphene’s exceptional electrical conductivity and mechanical strength make it an ideal candidate for slip ring contacts. Its application could lead to lower resistance, reduced wear, and longer operational life.

Carbon Nanotubes: Similar to graphene, carbon nanotubes offer high electrical conductivity and durability. Incorporating these materials into slip ring designs could result in significant improvements in performance and reliability.

2. Integration of Smart Technologies

The integration of smart technologies into slip ring capsules is another emerging trend. Smart slip rings are equipped with sensors and microcontrollers that enable real-time monitoring and data collection. This innovation can lead to predictive maintenance and enhanced system performance.

Real-Time Monitoring: Sensors embedded in the slip ring can monitor critical parameters such as temperature, humidity, and electrical resistance. This data can be used to predict potential failures and schedule maintenance proactively, reducing downtime and maintenance costs.

IoT Connectivity: The integration of Internet of Things (IoT) technology allows slip rings to communicate with other system components and remote monitoring platforms. This connectivity enhances the ability to manage and optimize system performance from a central location.

3. Miniaturization and Higher Density Designs

As technology advances, there is a growing trend toward miniaturization and higher density designs in slip ring capsules. This trend is driven by the need for more compact and efficient systems in industries such as medical devices, aerospace, and consumer electronics.

Miniaturized Slip Rings: Smaller slip rings with high performance are being developed to meet the needs of applications with stringent space constraints. These miniaturized designs do not compromise on performance, offering the same capabilities as larger counterparts.

Higher Density Channels: Engineers are working on increasing the number of channels within a single slip ring capsule without increasing its size. This development allows for more complex and multifunctional systems to be integrated into compact spaces.

4. Advanced Manufacturing Techniques

The adoption of advanced manufacturing techniques, such as 3D printing and additive manufacturing, is revolutionizing slip ring capsule design. These techniques enable the production of complex geometries and customized designs that were previously difficult or impossible to achieve.

3D Printing: 3D printing allows for rapid prototyping and the creation of intricate designs with precise tolerances. This capability is particularly useful for developing custom slip rings tailored to specific applications.

Additive Manufacturing: Additive manufacturing techniques enable the construction of slip rings with complex internal structures and integrated components. This approach can improve performance and reduce manufacturing costs.

Potential Future Applications and Advancements

1. Biomedical Devices

The future of slip ring capsules in biomedical devices looks promising, with advancements aimed at enhancing the performance and capabilities of medical equipment. Applications include advanced imaging systems, robotic surgical tools, and wearable health monitors.

Robotic Surgery: The development of ultra-compact and high-precision slip rings will enable more advanced robotic surgical systems, providing surgeons with greater control and accuracy.

Wearable Health Monitors: Miniaturized slip rings can be integrated into wearable devices, allowing for continuous health monitoring and data transmission without compromising comfort or mobility.

2. Renewable Energy Systems

Slip ring capsules will continue to play a critical role in the renewable energy sector, particularly in wind and solar energy systems. Future advancements will focus on enhancing efficiency and reliability to support the growing demand for sustainable energy solutions.

Wind Turbines: Innovations in slip ring design will improve the efficiency and durability of wind turbines, reducing maintenance costs and increasing energy output.

Solar Tracking Systems: Enhanced slip rings will enable more precise and reliable solar tracking systems, optimizing the orientation of solar panels to maximize energy capture.

3. Aerospace and Defense

The aerospace and defense industries will benefit from the ongoing development of slip ring technology, with applications ranging from satellite communication systems to unmanned aerial vehicles (UAVs).

Satellite Systems: Advanced slip rings will support the growing need for high-speed data transmission and reliable power transfer in satellite communication systems, ensuring continuous and accurate operation.

UAVs: The integration of lightweight and high-performance slip rings will enhance the capabilities of UAVs, providing improved control and data transmission for various defense and commercial applications.

4. Consumer Electronics

As consumer electronics continue to evolve, the demand for compact and efficient slip ring capsules will increase. Applications include virtual reality (VR) headsets, gaming controllers, and wearable technology.

VR Headsets: Slip rings will enable seamless 360° rotation and data transmission in VR headsets, providing users with an immersive and uninterrupted experience.

Gaming Controllers: Advanced slip rings will improve the performance and durability of gaming controllers, enhancing the overall user experience.

The future of slip ring capsules is marked by exciting advancements and emerging technologies that promise to enhance their performance, reliability, and versatility. From the integration of smart technologies and advanced materials to the development of miniaturized and high-density designs, these innovations will drive the next generation of slip ring capsules. As these trends continue to evolve, slip ring capsules will find new applications and deliver even greater value across a wide range of industries, from biomedical devices and renewable energy systems to aerospace, defense, and consumer electronics.

Keep an eye for more news & updates on Headlines.llc